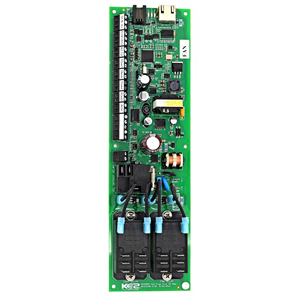

KE2 Compressor Sequencer OEM

- Overview

- Specifications

| Product Type | OEM |

| Min. Operating Temp. (F) | -40 |

| Max. Operating Temp. (F) | 140 |

| Regulatory Listing | cRUus |

| Voltage Rating | 100-240 |

| Alarm Option | Display, Email, Text with KE2 SmartAccess |

| Communication | KE2 SmartAccess, Ethernet TCP/IP, RESTful JSON API, BACnet/IP with KE2-EM |

| Datalogging | 30 Days Built-in, 365+ Days with KE2-EM |

| Refrigerants | R-404A, R-507, R-407A, R-407C, R-422A, R-422D, R-134a, R-22, R-717, R-438A, R-408A, R-409A, R-407F, R-410A, R-448A, R-449A, R-450A, R-452A, R-458A, R-513A |

| Compressor Control | Fixed Speed, Digital, Variable Frequency Drive (VFD), Unloaders |

| Application Type | Walk-in Cooler, Walk-in Freezer, Refrigerated Warehouse, Refrigerated Production Area, Blast Freezer, Refrigerated Showcase, Temperature & Humidity Control, Small-Medium Rack |

| Part Number | 21768 |

Read More Read Less

Want to learn more? Interact with our demonstration dashboard.

Try it Out-

Suggested Replacement Products

PRODUCT INFORMATION

-

Spec Sheets

-

Photometry & Revit (BIM)

-

Technical Documents (e.g. Instruction Sheets, MSDS, CAD)

-

Utility Rebate Search

-

Replacement Parts

-

Confidential Documents

-

Marketing Material (e.g. Brochures, Sell Sheets, FAQs)

-

Archived Documents

Document Type Description Updated View Installation Instructions Quick Start Guide – KE2 Compressor Sequencer OEM v1.01 // Q.2.60 (Archived) 3/1/2019 View -

Need Product Assistance? (e.g. How to Buy, Technical Support, Warranty)

How to Buy

KE2 Therm products are sold through a network of distributors and wholesalers across North America, as well as on OEM equipment. If you need assistance purchasing KE2 Therm products in your area, please contact us via the link below.

Technical Support

KE2 Therm is dedicated to providing outstanding technical support. Our standard business hours are Monday – Friday, 8AM-5PM Central Time, excluding holidays. The KE2 Therm YouTube channel and product literature answer most common questions. Please click on the video link below, see documents above, or feel free to call us at 1-888-337-3358 or email us at techsupport@ke2therm.com

• Videos

Warranty

Please click the appropriate link below to learn more about KE2 Therm terms & conditions and product warranty options.

View Stocked Products

-

Is the new stocked product detail helpful? Please tell us what you think, CLICK HERE.

Is the new stocked product detail helpful? Please tell us what you think, CLICK HERE.SKU data not available, please contact your local agent.

{{getMinimumDisplayedIndex()}} - {{getMaximumDisplayedIndex()}} of {{filteredStockedProducts.length}} results

(No Products Found){{result.Title}}{{result.Title}}{{result.Description}}Quantity{{(result.Quantity > 0) ? result.Quantity : 0}} in {{result.Location.substring(result.Location.indexOf("(")+1, result.Location.indexOf(")"))}}Total at all DCs: {{result.EnterpriseAvailability}}Distr. Price${{result.Price | number : 2}}Distr. PriceContact AcuityDistr. PriceContact RepDistr. PriceGET PRICEDistr. PriceNo pricing establishedNo Locations Could Be Found.

This catalog # is not available at any location at this time. Inventory is replenished daily, please check back or contact your local sales representative or agency further details.

Your session has expired. Click on the login link to view stocked product information.

Login/RegisterProduct information is not available at this time. Please try again later.Available Est. Ship Date Location In Transit {{loc.QUANTITY > 0 ? loc.QUANTITY : 0}} {{loc.ESTIMATED_SHIP_DATE}} {{loc.LOCATION}} {{loc.IN_TRANSIT_QUANTITY}} Restocking date is unavailable at this time. Location Est. Restocking Qty & Date {{transitDetail.QUANTITY > 0 ? transitDetail.QUANTITY : 0}}{{transitDetail.ARRIVAL_DATE ? transitDetail.ARRIVAL_DATE : "Date Not Provided"}} Available{{loc.QUANTITY > 0 ? loc.QUANTITY : 0}}Est. Ship Date{{loc.ESTIMATED_SHIP_DATE}}Location{{loc.LOCATION}}In Transit{{loc.IN_TRANSIT_QUANTITY}}Restocking date is unavailable at this time.Location Est. Restocking Qty & Date{{transitDetail.QUANTITY > 0 ? transitDetail.QUANTITY : 0}}{{transitDetail.ARRIVAL_DATE ? transitDetail.ARRIVAL_DATE : "Date Not Provided"}}View AllView Less

Compatible Products

- Controls

- Monitoring and Connectivity

- Accessories and Valves

KE2 Environment Panel (Humidity & Temp Con...

Monitor and control both temp and humidity, with a unique...

Orders entered before noon will ship same day, and orders entered after noon will ship next day within your given timezone.

Orders entered before noon will ship same day, and orders entered after noon will ship next day within your given timezone.

Standard Stock

Standard Stock